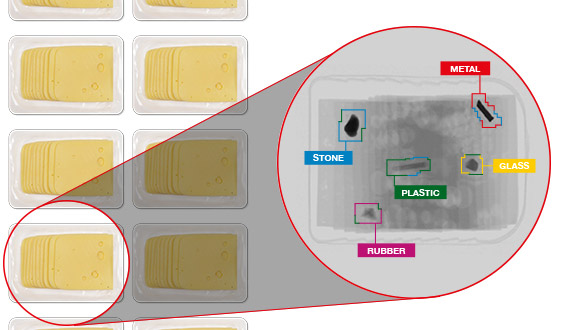

Creating and following good manufacturing processes are the first steps dairy processors take to bring their top quality products to the market and to avoid food recalls. Even with the best plans, strict adherence to regulatory requirements, and tenacious monitoring, the possibility that foreign objects will find their way into packages is always present. To keep consumers safe and to protect the brand’s reputation, dairy processors use detection systems, such as X-ray machines, as the last line of defense.

When selecting the optimal X-ray detection systems, dairy processors first should determine what product is being inspected. After deciding what product(s) the machine will handle and the function(s) for which the machine will be responsible, there are still a number of important factors to consider. Following are factors to consider when choosing an X-ray detection system.

Generators

Within an X-ray machine, the generator produces the X-rays that are transmitted through the product and foreign bodies. The generator’s available power output (voltage and current) is an important specification in the overall performance of the system.

Within an X-ray machine, the generator produces the X-rays that are transmitted through the product and foreign bodies. The generator’s available power output (voltage and current) is an important specification in the overall performance of the system.

Line sensors

While most machines just have one sensor, multiple sensors, can provide greater contrasting images–this is useful in applications that require the detection of lower density contaminants such as glass.

Diode pitch

Just as more pixels in digital cameras create clearer images, line sensors with a smaller diode pitch will allow for better resolution and increased ability to detect smaller contaminants. However, smaller diodes can also magnify “noise” that leads to distortion in the image.

Imaging software

The machine’s imaging software analyzes the line sensor signals to determine what is foreign material and what is good product. The power and functions of the X-ray system’s imaging software can be the single most important factor in the overall ability to detect foreign material.

Rejection

The size and weight of the products, as well as line speed, will factor into the decision. Either way, this mechanism is vital for removing bad products.

Certification

X-ray is regulated by the FDA as well as state agencies, and both users and vendors are typically required to follow various registration and usage procedures when installing and operating X-ray systems.

Software

Software has a huge impact on the internal adoption of X-ray technology. Due to advances in technology, it is typically quick and easy to set up pre-sets.

Application support

The results from X-ray inspection are dependent on the objects imaged and the proper setup of the machine. So, it is important to work with an experienced organization which can help align the equipment to the application.

Training

While X-ray systems are not complex to understand, training is essential to build the knowledge to use them safely and compliantly, along with being able to maximize their effectiveness on the line.

Cost of ownership

It is important to assess which type of X-ray will suit the requirements, along with the quality of the support, available training, and the provision of ongoing service maintenance before making a decision.

X-ray detection machines can be used at various critical control points (CCP) on a production line, and their installment can strengthen both quality control and quality assurance for a dairy processor. X-ray systems that are commonly found at the end of the production line are used to identify defects before products are dispatched and sent to the retailer or distributor. Inspection of incoming ingredients may offer important benefits, such as protecting machinery and/or eliminating contaminants before they can be fragmented (by downstream machinery) into pieces that may be too small for detection at end-of-line CCP inspection points.

Unsurprisingly, the same X-ray technologies may perform differently depending on the characteristics of the product. For example, the performance can be reduced on thick, dense products, such as large blocks of cheese.

Unsurprisingly, the same X-ray technologies may perform differently depending on the characteristics of the product. For example, the performance can be reduced on thick, dense products, such as large blocks of cheese.

In addition to inspecting for physical contaminants, X-ray systems are widely used to perform additional quality control checks such as estimating mass, counting components, identifying missing or broken products, monitoring fill levels, and inspecting seals for food entrapment.

The limitations and challenges that dairy processors face in incorporating the ideal X-ray detection system in their facilities may differ, but generally the application itself can be the biggest challenge. For example, a processor’s line may run an extensive range of products that differ in size and weight, and selecting a machine that can handle the largest product by size while still meeting the speed and/or sensitivity requirements of a smaller package is a common challenge.

To address those challenges, Ishida, Heat and Control®’s longtime partner, takes product safety and quality assurance to the next level with their cutting-edge X-ray machines, including the industry leading IX series.

The photon counting dual energy IX-PD series X-ray machine employs an alternative sensor and accompanying image processing technology to give the IX series’ highest sensitivity and accuracy of low-density and minute foreign object contaminant detection. This technology is able to compare and to recognize the physical property differences between product and foreign objects, reducing the rate of erroneous detection.

Ishida’s IX-GN and IX-EN X-ray detectors incorporate their patented Genetic Algorithm (GA) image processing which delivers superior accuracy. In addition to the flexible customization options for GA setting creation, many typical GA settings are already stored on the machine, streamlining set-up. Also, up to four (4) different GA settings can exist at the same time on the IX-GN series units and up to two (2) different GA on the economically priced IX-EN models.

“To keep consumers safe and to protect the brand’s reputation, dairy processors use detection systems, such as X-ray machines, as the last line of defense.” Todd Grube, Heat and Control Manager of Inspection Systems.