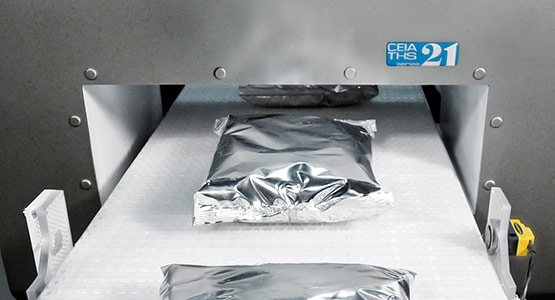

CEIA

Pharmaceutical Metal Detection

CEIA's THS/PH21® Series and THS/PH210® Series metal detection systems offer superior sensitivity, construction quality, and reliability characteristics that make them the most suitable and effective solution to automatic elimination of metal contaminants in pharmaceutical products.