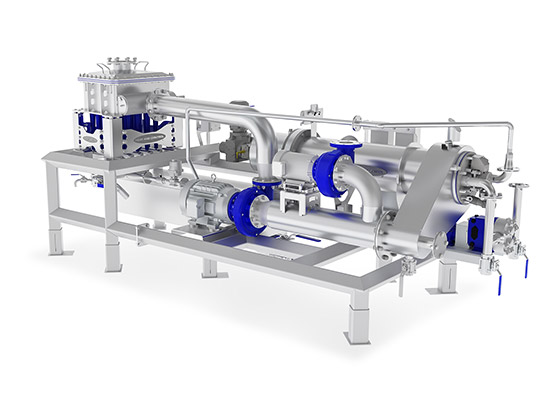

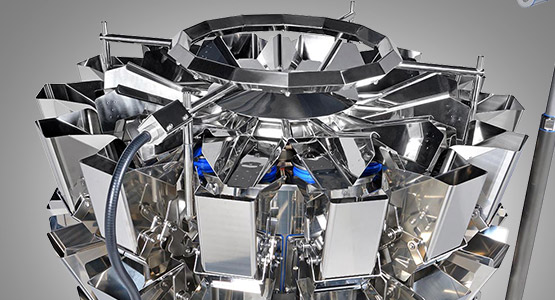

RAW PRODUCE HANDLING

Cascade Water Recirculation and Water Sustainability

With water sustainability at its core, Cascade Water Recirculation is a design methodology that looks holistically at your raw produce processing area to significantly reduce freshwater consumption. Learn more about this new process design approach at our booth or attend our SNAXPO Education Session April 1 at 11:30am-12:00pm with our guest speaker Rick Bajema, Director of Raw Material Processing (GET DETAILS HERE).