Bakery Foods

We design equipment specifically for bakery food products, such as bagels, donuts, breakfast pastries, fruit-filled pies, cookies, crackers, and pretzels.

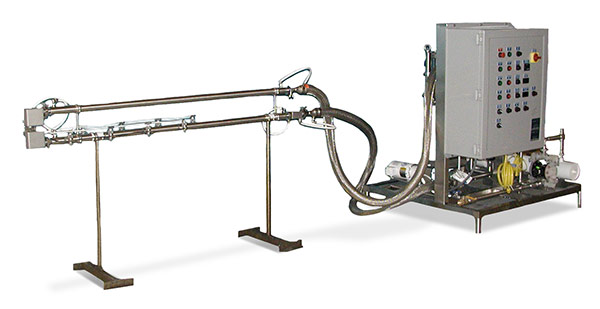

A user-friendly spray system providing continuous, metered "airless" oil application using our patented two-hole nozzle design that delivers a fan shaped spray pattern for optimal product coating. The Spray Dynamics MS III is designed for use with our coating drum, blender, belt, or auger systems.

Ensure maximum application for high-throughput production lines requiring oil addition of 120 pounds per hour and higher with our "airless" delivery design feature.

IDEAL APPLICATIONS:

We design equipment specifically for bakery food products, such as bagels, donuts, breakfast pastries, fruit-filled pies, cookies, crackers, and pretzels.

Meet demand while ensuring high quality, reducing labor costs, and improving yields with reliable automated systems for cannabis products such as gummies, edibles, dried flower, and crumble.

We provide reliable and efficient product handling, weighing, and inspection systems for breakfast cereals and other nutritional grains, from flakes to granola and oats.

We are the leading solution provider and make the highest quality extruded or sheeted corn chips and offer complete line expertise, from raw corn to packaging.

We transform the raw recipe into the extruded, pulse, and legume snacks consumers know and love. We provide solutions to create cheese balls, cheese puffs, namkeen, and green peas.

Our french fry and formed potato product systems are the workhorses of the industry. We process a broad range of styles, including straight cut fries, crinkle cut fries, curly fries, potato wedges, and variety of potato co-products. Working with our strategic partners, we are capable of full turnkey solutions, from potato receiving through palletizing.

Our pellet snack solutions deliver uniform processing of pork rinds, sea and rice pellets, other grain-based pellets, and collet snacks.

Start with dry corn and manage every step of the way including the cook, simmer, and soak process followed by our complete solution, start-to-finish, to make all shapes of tortilla chips.

Simplify masa production by starting with corn flour and a masa flour mixing system, followed by sheeting and beyond to create all shapes of tortilla chips.

The Corn Masa Maker System (CMMS), Masa Maker, is our revolutionary way to make fresh masa faster. Produce high quality masa in minutes rather than hours compared to traditional systems.

Select a department to email: