Heat and Control® is showcasing their equipment solutions which incorporate the most advanced equipment technologies during PACKEXPO International 2024. With live equipment demonstrations multiple times every day, everyone can see their state-of-the-industry innovations in action.

Attendees can talk with experts at the Heat and Control booth (# N-6106) which features more than 9,700 sq. ft. of industry leading equipment.

Integrated Systems

Check the demonstration schedule posted on the Heat and Control booth for their new integrated systems to make sure you see the ones that best address your production needs.

Introducing A Symphony of Seasoning Technology

New and for the first time from the industry leader in seasoning application—a transformation in seasoning operations. Solve seasoning allergens and operation issues with Symphony’s new seasoning technology which improves accuracy and efficiency and reduces waste for both on-machine and in-kitchen seasoning applications.

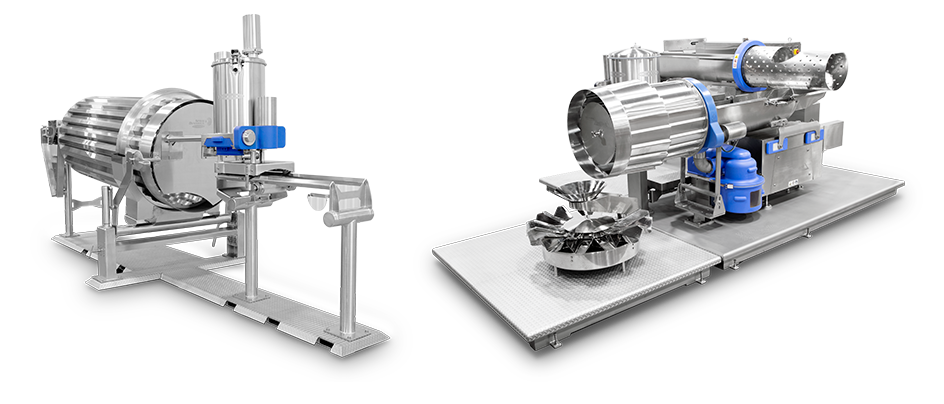

Ishida Integrated Snack Packaging

The ultimate in high performance, an integrated and complete packing room solution for snack foods which utilizes Heat and Control’s Lift & Tip vertical incline conveying solution to feed Ishida CCW-AS Series multihead weigher, Inspira VFFS snack bagmaker, CEIA® metal detector, Ishida TSC seal checker, and Ishida ACP Series case packer.

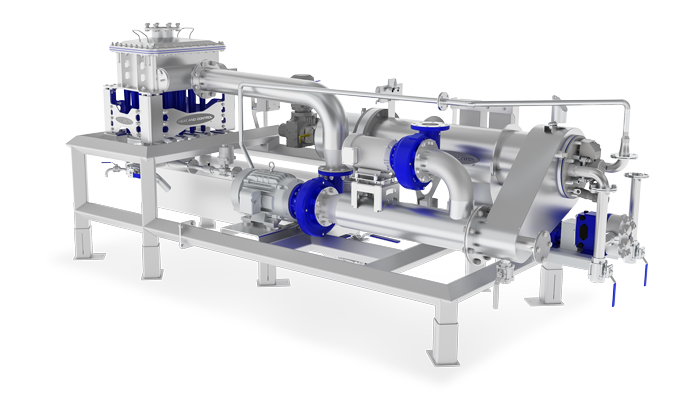

Cascade Water Recirculation

With water sustainability at its core, Cascade Water Recirculation is a design methodology that looks holistically at the raw produce processing area to significantly reduce fresh water consumption. Technology showcased includes Slice Wash Support Module (SWSM) and Process Recirculation Support Module (PRSM). Talk with experts about how SWSM’s and PRSM’s approach to water sustainability can help processors achieve new targets.

Learn more about this process design approach by visiting the Processing Innovation Stage on Sun., Nov. 3, at 12:00 pm where Rick Bajema, Heat and Control Director of Raw Material Innovation, will share his expertise and his insights about Cascade Water Recirculation and Water Sustainability for the food industry.

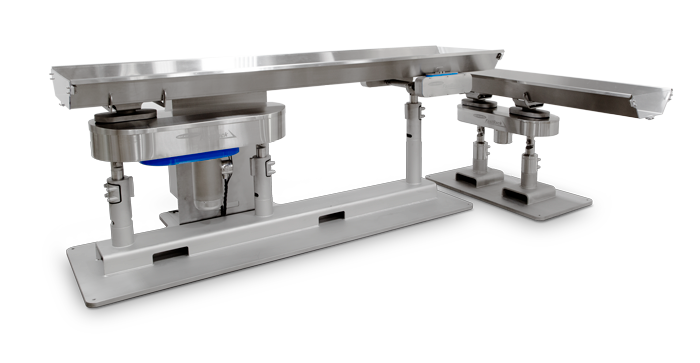

Next Generation FastBack® Horizontal Motion Conveying–size up with FastBack 4.0 (250)

The next generation of FastBack horizontal motion conveying is now available in mid-range capacity with FastBack 4.0 (250). Using a patented linear to horizontal motion to move product along the line with gentle handling, the FastBack 4.0 generation takes horizontal motion further. See both the new FastBack 4.0 (250) and the previously launched FastBack 4.0 (100) models.

Ishida CCW Series Multihead Weighing–Where Innovation Weighs Supreme

Take a cruise to the “Inspection Island”

If finding reliable quality control assurance systems sounds like a holiday in the making, see the Heat and Control, along with partners Ishida and CEIA, line-up of inspection and quality control solutions in one location. A destination where you can talk inspection with experts, test out the technology, then settle back and relax for the rest of the show!

Ishida IX Series X-ray

Check out the latest IX-PD series X-ray that features unmatched X-ray performance using a photon counting, direct conversion sensor. Coupled with Ishida’s proven image processing and Genetic Algorithm software, the IX-PD produces the highest resolution images with best-in-class detection of small metal fragments and low-density contaminants.

Ishida DACS Series Checkweighers

Options are aplenty for any checkweighing application using Ishida’s high sensitivity load cell technology.

CEIA Metal Detection

The innovator and leader in multi-spectrum metal detection, CEIA is widely known for metal detection expertise in various industries. A broad range of metal detection for the food industry will be on the floor, including two advanced tools to support high performance metal detection efficiency: THS/PH210® Metal Detector Series and THS/PH210-FFV.

CEIA® Launches Advanced THS/PH210® Metal Detector Series with Full FDA Compliance

CEIA introduces its latest advancements in pharmaceutical metal detection: the THS/PH210 Series metal detectors. These cutting-edge systems are fully compliant with FDA 21 CFR Part 11 and FDA 21 CFR 210, delivering unparalleled performance, security, and traceability in pharmaceutical applications. The THS/PH210 Series metal detectors meet the stringent criteria outlined in FDA 21 CFR Part 11, ensuring that user access, data protection, and traceability are maintained at the highest standard. User access is secured through a User Name and Password login system and managed by a System Administrator who controls individual user profiles. This ensures only authorized personnel can access the system, safeguarding the integrity and the security of operations.

CEIA launches Innovative Valve System for Pharmaceutical Inspection Applications: THS/PH210-FFV

CEIA announces the launch of its cutting-edge valve system, the THS/PH210-FFV, designed specifically for pharmaceutical powder inspection. This new system offers advanced functionality to meet the stringent sanitation and performance standards required in modern pharmaceutical manufacturing. Pharmaceutical production frequently involves small batches and multiple raw materials, necessitating regular and thorough equipment cleaning. The THS/PH210-FFV metal detector with valve system has been designed to optimize these processes by offering superior inspection and sanitation capabilities, ensuring compliance with hygiene standards and enhancing production efficiency.

CEIA THS/Production 4.0

A CEIA-ERP API interface that provides acquisition and report capability for THS 21 Metal Detection Systems back to the factory management software (Microsoft® Dynamics NAV, SAP, ORACLE® ERP) connects and acquires data from multiple THS detectors via wired or wireless LAN and enables data base management and back-up of metal detector events.

CEIA AUTOTEST and AUTO-QC™TEST FUNCTIONS

These functions ensure continuous background real-time monitoring and stabilization of the amplitude and phase response for each working frequency, continuous compensation of environment, age-related changes and immediate alerting in the case of permanent out of standard conditions.

Training Solutions

Heat and Control has enhanced training capability and delivery with the introduction of myTraining, a self-paced eLearning training option for Heat and Control supplied equipment using a Learning Management System (LMS) and will be demonstrating myTraining at PACKEXPO International.

eLearning can help manufacturers expand training capability with Heat and Control equipment learning resources via myTraining LMS, provide a standardized equipment training plan to plant operations personnel, and provide new operators with general equipment and operation information more quickly. eLearning can be used in conjunction with other training methods, such as supplementing with instructor lead training for Ishida equipment at the Heat and Control Pennsylvania, USA location. Heat and Control customers can work with the Heat and Control myTraining Solutions team to develop customized and blended training plans for new projects/commissioning, installation, or ongoing training content access through eLearning subscription.