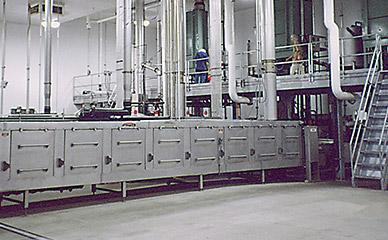

Corn Cooking & Soaking

Achieve complete control of corn processing including simmering, soaking, cooling, and transfer between each stage.

You can rely on our complete systems to prepare baked and fried tortilla products from corn and grain-based flours. From corn and masa preparation to inspection of packaged product, we can provide everything you need, including special continuous fryers for tostada and taco shell production.

Corn Cooking & Soaking

Washing & Dewatering

Corn Grinding / Masa Preparation

Sheeting

Toasting

Conditioning

Frying

Fryer Support Module

Oil Filtration

Oil Heating

Oil Cooling

Oil Storage

Product Cooling

Energy Saving

Pollution Control

Seasoning

Conveying

Inspection

Support Structures

Controls & Information

Achieve complete control of corn processing including simmering, soaking, cooling, and transfer between each stage.

Our full corn washing systems includes everything you need to precisely control the washing process of corn including controlling lime content, removing hulls, and separating corn from simmer-soak water.

Whether you create your own masa using a corn cook process, use our revolutionary Masa Maker™ system, or simply out-source your flour, we offer a variety of methods to prepare masa ready for sheeting.

Sheeting systems to create any manner of corn product including uniform chips, tortillas, tostadas, and taco shells.

Control moisture and customize toast points for unique flavor, texture, and appearance of corn products such as tortilla chips, taco and tostada shells, and tortillas.

Prevent blistering and oil pockets in corn products such as tortilla chips and taco/tostada shells by equalizing chip moisture.

We provide more choices when it comes to selecting a new fryer. Choose from natural gas, oil, steam, thermal fluid or electric heating. Optimal product handling, uniform oil heating and flow control, efficient fines removal, fast oil turnover, and clean-in-place sanitation are all part of the fryer package that produces the highest quality product with a long shelf life.

Significantly reduce the time and cost of fryer system installation by centralizing oil pumps, filters, valves, piping, and other components on a Fryer Support Module.

Remove particulate material from the frying oil to preserve oil quality and to help prevent spoiling of the end-product.

Our cooking oil heating and energy recovery systems are designed to provide high energy efficiency, preserve the quality of the cooking oil, and maintain accurate temperature control for uniform cooking.

Save time by managing the cooking oil cooling process as you prepare the fryer for shut-down or sanitation. This also helps preserve cooking oil quality.

Safely transfer and store cooking oil during system cleaning or maintenance while preventing spoilage or solidification.

Control the end of the cooking cycle by effectively managing the temperature of your cooked product. This ensures high quality as well as prepares it for the next stage of your process, such as seasoning or packaging.

Choose from a variety of heat management solutions that maximize energy-efficiency and reduce energy costs. Sustainable efficiency and environmentally safe operation are key design elements.

Reduce pollution such as oil mist, particulates, and odors from fryer exhaust emissions.

Our unbeatable seasoning showcase includes a variety of systems that provide consistent and uniform seasoning coverage for all kinds of corn products.

Our conveying and product handling systems include product transfer systems, horizontal motion conveyors, and accumulation systems that provide a gentle, smart, and dependable product transfer solution.

Anywhere along the line, protect your consumer and your equipment. Efficient detection of foreign objects is critical to consumer safety, brand survival, and will also protect machinery and prevent downtime. Correct weight ensures the consumer gets what they expect. We offer a complete line of metal detectors, checkweighers, and X-ray inspection systems from the leading manufacturers: Ishida and CEIA.

We design customized modular platforms and support structures that dramatically reduce time and cost of equipment installation. All support structures are designed with hygiene and safety in mind.

Select a department to email: