Bakery Foods

We design equipment specifically for bakery food products, such as bagels, donuts, breakfast pastries, fruit-filled pies, cookies, crackers, and pretzels.

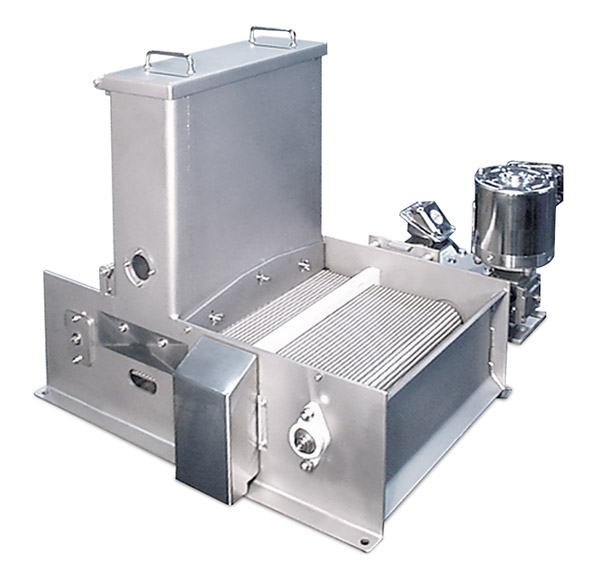

Precisely apply salt or seasoning to snacks, nuts, crackers, and/or prepared foods across conveyors by using a metering belt for uniform application while eliminating lumps.

Accurately adjust the dispensing rate and volume of seasoning side-to-side across the conveyor width up to 59". The durable stainless steel construction is built to USDA sanitation standards and fits most existing systems.

IDEAL APPLICATIONS:

We design equipment specifically for bakery food products, such as bagels, donuts, breakfast pastries, fruit-filled pies, cookies, crackers, and pretzels.

We are the leading solution provider and make the highest quality extruded or sheeted corn chips and offer complete line expertise, from raw corn to packaging.

We transform the raw recipe into the extruded, pulse, and legume snacks consumers know and love. We provide solutions to create cheese balls, cheese puffs, namkeen, and green peas.

Producing the world’s best tasting potato chips, our industry leading end-to-end systems process and package the highest quality potato chip products.

Our industry leading end-to-end systems process, inspect, and package the highest quality batch kettle-style / hard-bite chips.

Our high-performance continuous kettle-style / hard-bite potato chip processing and packaging solution produces the world’s most popular kettle-chips.

Our value-added systems prepare and cook consistently superior beef, pork, chicken, turkey, fish and other meat products including alternative meat to create a distinctive quality that stands out in the marketplace.

We process and package all types of nuts, including roasted, seasoned, coated, and glazed, with our turnkey systems.

Our pellet snack solutions deliver uniform processing of pork rinds, sea and rice pellets, other grain-based pellets, and collet snacks.

Our systems consistently produce value-added prepared foods, including onion rings, pizza rolls, taquitos, chicken pot pies, pot stickers, egg rolls, ready meals, and alternative meat products.

Start with dry corn and manage every step of the way including the cook, simmer, and soak process followed by our complete solution, start-to-finish, to make all shapes of tortilla chips.

Simplify masa production by starting with corn flour and a masa flour mixing system, followed by sheeting and beyond to create all shapes of tortilla chips.

The Corn Masa Maker System (CMMS), Masa Maker, is our revolutionary way to make fresh masa faster. Produce high quality masa in minutes rather than hours compared to traditional systems.

Select a department to email: