Spiral Oven Brochure - English

Spiral Oven Brochure - English

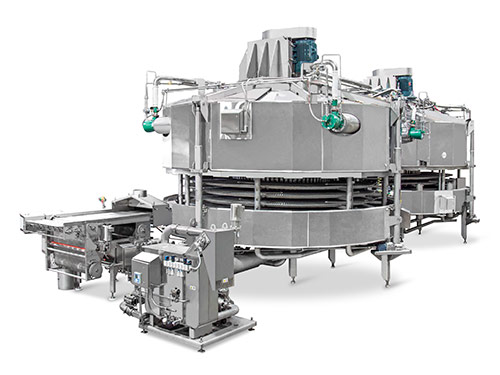

The space-saving spiral oven’s 360° airflow delivers continuous uniform cooking across all belts for faster cooking, higher yields, and increased production output. Available in single or twin drum configurations, the spiral oven is built to suit your unique product requirements.

Complete Turnkey Solutions for the French Fry Industry - English

Complete Turnkey Solutions for the French Fry Industry - English

Our french fry and formed potato product systems are the workhorses of the industry. We process a broad range of styles, including straight cut fries, crinkle cut fries, curly fries, potato wedges, and variety of potato co-products.

Ishida's Sanitary Machines - Weighing, Inspection and Packaging - English

Ishida's Sanitary Machines - Weighing, Inspection and Packaging - English

Ishida offers a wide range of sanitary machines that offer self draining, continuous weld, IP69K compliance, and open frames to meet hygienic standards and improve productivity for your food processing and packaging lines.

Complete Snack Processing and Packaging Solutions - English

Complete Snack Processing and Packaging Solutions - English

From unloading raw produce to frying, conveying, seasoning, packaging and inspection, we provide all the equipment and services required to make the highest quality snack foods while achieving higher capacities and lower production costs.

Ishida IX-EN X-ray Inspection Systems - English

Ishida IX-EN X-ray Inspection Systems - English

Enhance quality control on your production line, both affordably and effectively, thanks to Ishida’s Genetic Algorithm (GA) image processing and 5-stage image analysis. This system provides reliable X-ray inspection for detecting a range of high- and low-density foreign bodies, such as stainless metal, glass, plastic, bone, and rubber as well as identification of product defects and weight estimation.

Autonomous Packaging – Checkweighers - English

Autonomous Packaging – Checkweighers - English

Check weighing is key for delivering what your consumers expect by providing accurate verification of a package's weight or count and detecting missing components.