Mastermatic Roll Salter Brochure - English

Mastermatic Roll Salter Brochure - English

Accurately and evenly apply salt and seasoning across the entire conveyor width for a variety of product types as they leave your processing and cooking equipment.

Multihead Weighing - Marinated Chicken Application Story - English

Multihead Weighing - Marinated Chicken Application Story - English

A top barbecue-ready chicken producer has used an Ishida Screw Feeder multihead weigher to improve both speed and accuracy in the packing of sticky marinated chicken pieces.

Multihead Weighing - Fresh Chicken Application Story - English

Multihead Weighing - Fresh Chicken Application Story - English

The IP69K-rated, open frame screwfeeder weigher handles products that are sticky, soft, or too difficult to move using vibration, instead uses a classic rotating screw system to gently transfer the product with accuracy. A wide choice of screw configurations in numerous shapes and sizes to suit different product characteristics is available as well.

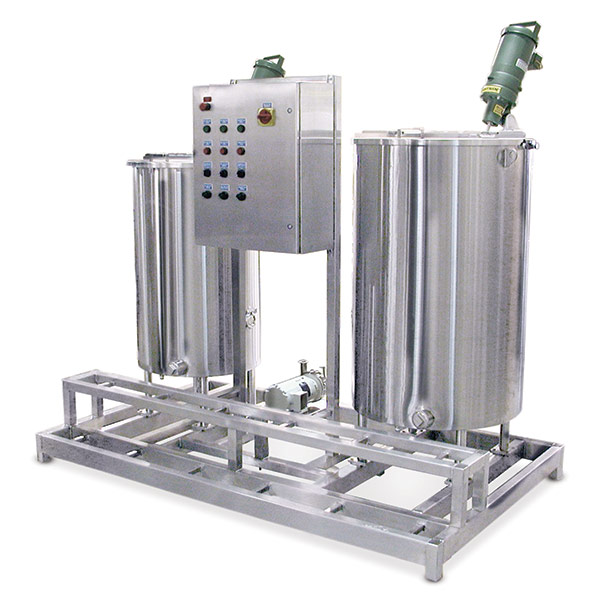

Spray Dynamics Mix-Use Twin Tank Skid System Brochure - English

Spray Dynamics Mix-Use Twin Tank Skid System Brochure - English

Isolating the mixing process in separate mix and use tanks improves the consistency of the blended product. The entire tank system can be heated or chilled and can be located on a skid making it self-contained and easy to handle.

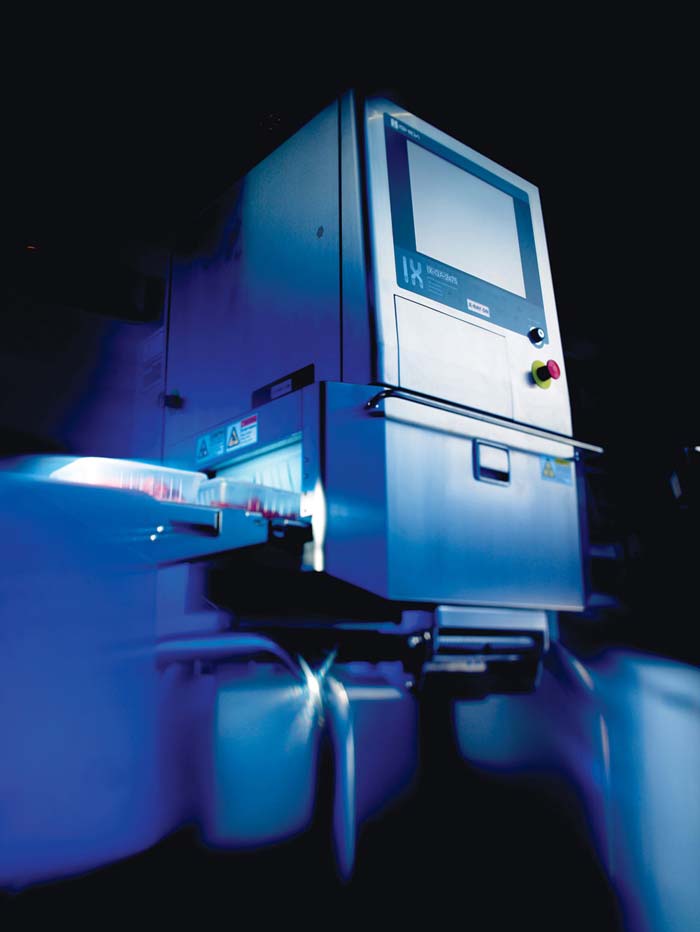

Do I need X-ray inspection? - English

Do I need X-ray inspection? - English

Manage risk and improve quality by finding foreign objects and detecting product defects before they reach the consumer.

Spray Dynamics Questions and Answers - English

Spray Dynamics Questions and Answers - English

Spray Dynamics is a leading innovator of equipment for the controlled application of liquid and dry ingredients on a wide range of food products. Lucas Bell, General Manager of Spray Dynamics, answers a few questions to help you get to know the innovations and the team.