Food Processing

We have invested in decades of research and development to advance the quality of food products. Our commitment to the industry has revolutionized food production and helped brands create products that consumers love.

We have invested in decades of research and development to advance the quality of food products. Our commitment to the industry has revolutionized food production and helped brands create products that consumers love.

We’ve worked with food companies around the world to create products consumers love. Our comprehensive range of seasoning solutions deliver top performance, efficiency, application accuracy, and of course, great flavor.

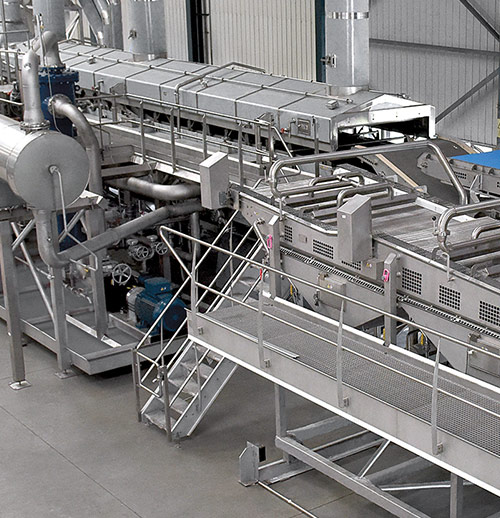

We look at all aspects of your plant and proposed equipment, then design a customized support structure and platform system that meets hygiene standards, drives efficiency, reduces installation time, and helps manage costs.

Protect your consumer and your equipment with industry leading package testing and contaminant detection technology. Efficient detection of foreign objects is critical to consumer safety and brand survival and will also protect machinery and prevent downtime.

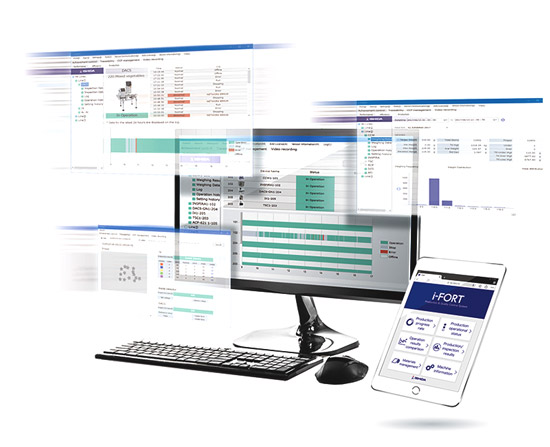

We’ve created the next generation of smart controls with the look and feel of a modern app. Plant personnel become experts thanks to situational awareness themes, advisory notifications, and real-time vitals that transform ROI.

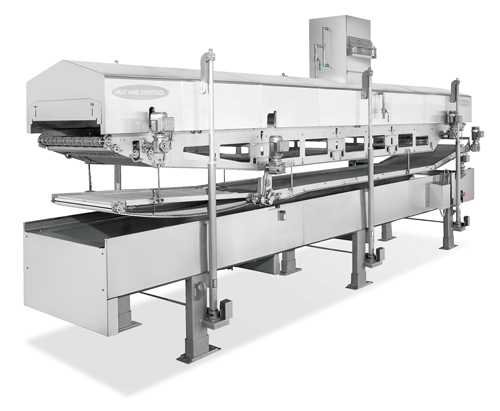

Deliver better taste with a tried-and-true method that can handle a variety of coatings and product types.

Gain access to all the equipment and expertise you need to efficiently transport, wash, peel, slice, and dice root vegetables—raw or cooked.

In this article, we explore 6 key considerations for selecting an industrial fryer tailored for French fry production. Ready to unlock the key to superior French fries? Let’s examine some of the key factors that can enhance efficiency, maintain product quality, and address common production…

myTraining is a service that aims to provide eLearning go-to resources for Heat and Control supplied equipment to empower your operational team when they need it

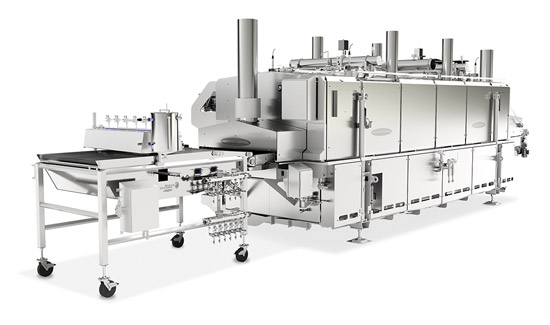

Unrivaled Frying Control and PerformanceWe offer a diverse range of heating options, allowing you to choose between natural gas, oil, steam, thermal fluid, electric heating, KleenHeat® and Greenheat. Our fryers boast optimal product handling, uniform oil heating and flow control, efficient fines…

E-mail the Heat and Control training team to ensure the safety, productivity, and longevity of your production lines by providing skills training for your personnel. We teach your line operators to expertly identify situations before they become a problem, have confidence with safety protocols, and…

Nutraceuticals are increasingly becoming a part of the food industry as consumers seek products that offer health benefits beyond basic nutrition. Nutraceuticals are driving collaborations between the food industry and pharmaceutical companies that can facilitate the development of innovative…

With their signature crunch and seemingly endless flavor varieties — kettle chips are an enduring consumer favorite. But what’s the secret to this enduring popularity — and what is it exactly — that makes them so very special? The answer begins with their cooking method. This type of potato chip…

Learn how our partner, CEIA, provided a solution to integrate a Metal Detector system into their customer's existing sachet packaging line with limited space constraints.

Regulations Regulatory bodies set strict standards for product measurements to ensure fair trade practices as well as to protect consumers. Adherence to these regulations is essential to avoid legal consequences and to maintain a reputable business. The cannabis industry is heavily regulated and…

Many factors are driving the shift in consumer demand from animal proteins to meat alternative products. Health and nutrition, ethical eating choices, religious views, animal rights and sustainability are all contributing to more conscious purchase decisions and the plant-based alternatives market…

More Flavors and Mixed Products Snack producers have been increasing flavor and mix options in an effort to meet consumer interest in global and non-traditional flavor options. Consumers can now find chips in a variety of flavors (e.g., hot dog, fruit, cappuccino, sushi, butter chicken, beer…

What are the main styles of breaded seafood? Breading and battering of seafood products ranges from a very light — to very heavy flour, crumb, or tempura coating. Flour coatings offer a softer coating and bite whereas crumb coatings provide the crispy texture many processors want. Tempura coatings…

Get creative with your recipes and deliver balanced blends of all kinds of products. Our blending systems offer high accuracy, consistency, and operator friendly control.

Get creative with your recipes and deliver balanced blends of all kinds of products. Our blending systems offer high accuracy, consistency, and operator friendly control.

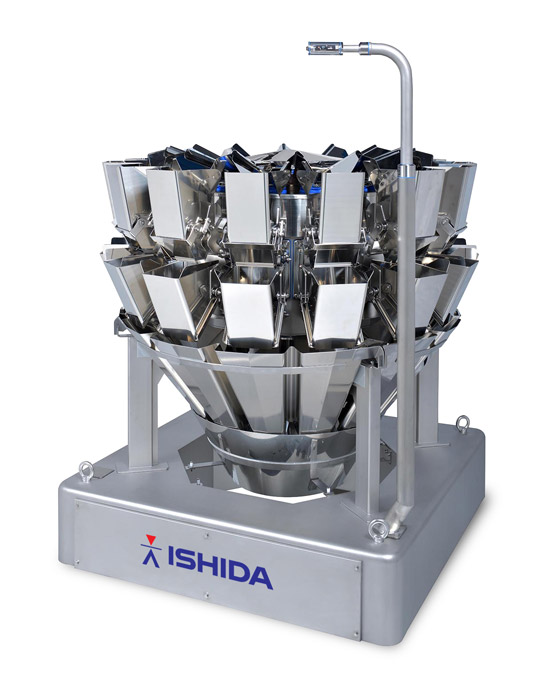

Their recipe for building trust for CCW Ishida’s long history in the world of weighing began in 1893 when they became Japan’s first private weighing equipment manufacturer during a new age of industrial modernization. Initially introduced for food product applications, computer combination…

When selecting the optimal X-ray detection systems, dairy processors first should determine what product is being inspected. After deciding what product(s) the machine will handle and the function(s) for which the machine will be responsible, there are still a number of important factors to…

The FastBack 4.0 streamlined and robust design has higher capacity, cleans easily, runs quietly, reverses instantly, and has 70% fewer moving parts. With no pinch points or moving arms to cover and to protect, the working environment is safer and more streamlined. Innovation and dependability…

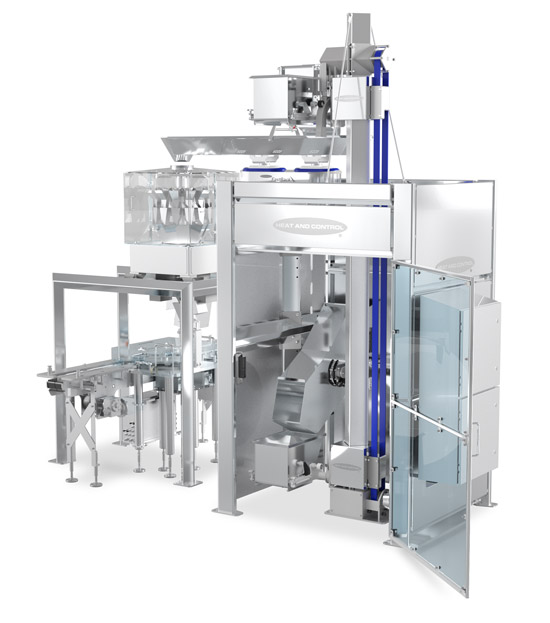

The Atlas Series (Atlas), the previous snack bagmaking model series, revolutionized snack bagmaking technology and became an industry benchmark in high-speed snack operations. Atlas’ versatile twin-jaw system and innovative continuous back seal system were key to its success in the industry. Always…

Ready meals have come a long way and modern consumers are spoilt for choice. The tasteless TV dinner is a thing of the past and today’s options cater for almost every taste and nutritional consideration. High protein, gluten free, organic and plant-based options are all trending and there’s a…

The Advantage Series (AS) multihead weigher’s advanced automation raises the bar in high speed challenging weighing applications, delivers unbeatable value, improves manufacturing and packaging efficiencies to assure a fast return on investment, and improves product quality and safety.

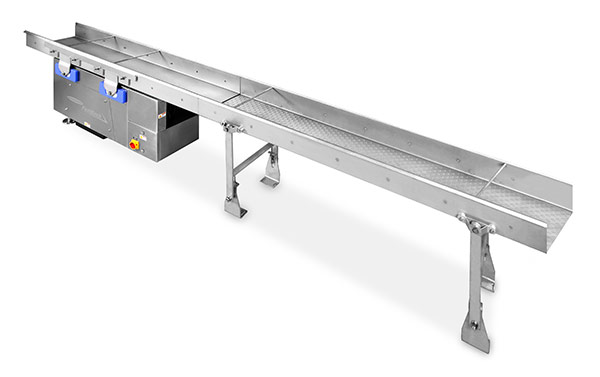

Compact and highly sanitary conveyor system that gently moves your products vertically to feed your weighing and packaging operation.

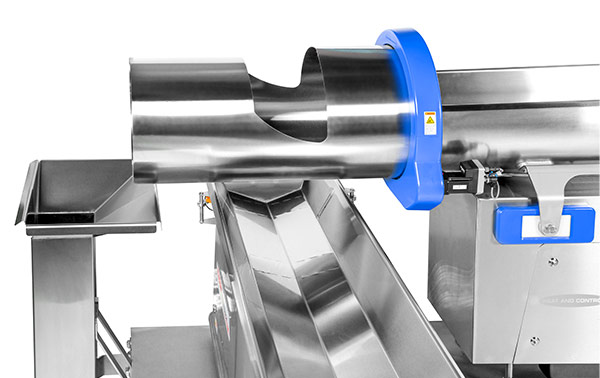

The patented circular to linear motion design gently handles the product so it is undamaged and the coatings are undisturbed, providing the ultimate performance and flexibility and the industry’s highest travel rates and flow rate capacity.

This groundbreaking proportional distribution system by FastBack uses unique cylindrical outlets that rotate to divert a proportional portion of product, so the main product supply continues to flow as it allocates amounts to individual weigher/bagmaker stations. Downstream stations are no longer "…

Today’s consumers have busier lifestyles, causing many of them to replace standard meals with snacking options. To address this trend, many snack manufacturers are offering a wider variety of flavors and portion sizes, so product runs can sometimes be shorter, making changeover time a bigger factor…

Food safety is critical Metal is one of the most common contaminants in the food manufacturing industry because it is a fundamental component of the manufacturing equipment and machinery itself. Many machines used in harvesting and processing food are comprised primarily of metal, and as a result…

Ideally, after a product is packaged, it is ready to be boxed and shipped to a customer. Unfortunately, that is not always the case—the product may be underweight or overweight, may have become damaged during production, or may contain foreign material, such as a piece of metal from a processing…

Poultry is the world’s primary source of animal protein and has increased fivefold (FAO)since the 1960s. As global fast-food chains continue to benefit from consumers seeking convenience, poultry products in the take-out market are expected to expand. Breaded chicken is a very popular poultry…

Potato chips are consistently a top seller in the highly competitive snack food market. To maintain popularity, manufacturers have developed a wide variety of flavors and styles. The manufacturing process, however, is fairly similar between them and manufacturers generally seek common objectives: a…

The photon counting dual energy IX-PD series X-ray machine employs an alternative sensor and accompanying image processing technology to give our highest sensitivity and accuracy of low-density and minute foreign object contaminant detection. This technology differentiates with high accuracy…

Potato chips are consistently a top seller in the highly competitive snack food market. To maintain popularity, manufacturers have developed a wide variety of flavors and styles. The manufacturing process, however, is fairly similar between them and manufacturers generally seek common objectives: a…

Potato chips are consistently a top seller in the highly competitive snack food market. To maintain popularity, manufacturers have developed a wide variety of flavors and styles. The manufacturing process, however, is fairly similar between them and manufacturers generally seek common objectives: a…

This market-leading fryer is used to produce most of the world’s potato chips. As the industry standard, our potato chip fryer delivers superior product quality, clean operation, and total reliability.

Manufacturing dry pet food involves the same processes as many other processed foods. The most common application for coating of dry pet food kibble or pet treats involves applying sequential coatings of liquid fat/oil, followed by adding a liquid digest or palatant, and lastly, applying a powdered…

What advantages do flexible (baking and snack) pouches have over other forms of packaging? The VFFS process produces pillow bags in extremely accurate weights at a high-capacity rate. The main advantage is that flexible pouches can be produced efficiently at high speeds to maximize processing…

What are the latest innovations in the field of equipment for frying, as part of potato processing? Heat and Control is pioneering a new range of French Fry equipment covering the full range of throughputs from 3 tph to 40 tph. We also have the industry’s most advanced vacuum frying systems,…

Pre-Dust Most product is pre-dusted to improve batter adhesion and total coating pickup; smooth or hard surface substrates usually require pre-dusting. Batter needs some amount of roughness and dryness on which to adhere and pre-dusting a substrate creates an excellent surface. Frozen substrates…

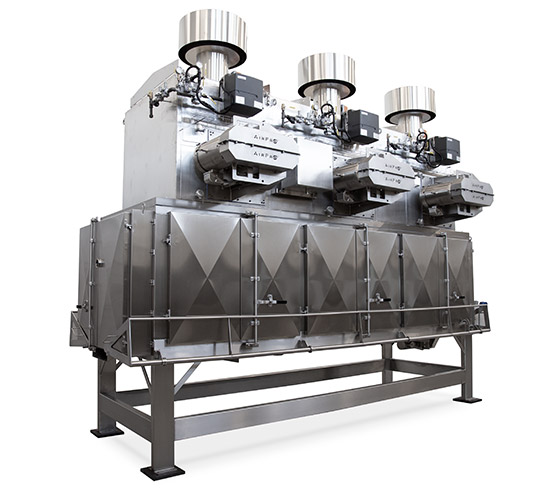

A high performance industrial linear air frying system that provides a means to continuously produce a “fried-like” product using a controlled application of topical oil followed by the uniform flow of pressurized, high velocity cooking atmosphere from an impingement oven.

Since deterioration is a multi-faceted problem, processors need to tackle the issue on several fronts—understanding their market and their environmental needs, selecting the appropriate frying system, determining the oil that is best suited to their frying system and product, and following good oil…

The world consumes a lot of potato, and potato processing lines are some of the largest and sophisticated in the food industry especially in terms of volume of throughput and capacity. In this Q&A, Blake Svejkovsky shares his knowledge of conveying systems and how to apply conveying solutions…

Namkeen, the home of legume snacks When it comes to legume snacks, Namkeen leads the way in variety and flavor. Namkeen is a broad term for salty snacks traditionally consumed in South Asian cultures, covering a range of products including whole legumes such as green peas, chickpeas, peanuts,…

Increase productivity with the Ishida AL-AI high-speed price labeller which automates the task of pricing food products, such as bento boxes or other prepared dishes.

In the 1940s, fried tortillas evolved into mass produced tortilla chips, marking the beginning of corn-based products joining the mainstream snack food industry, and are now one of the world’s most popular snack foods. Not surprisingly, there are different processes and equipment for each line of…

Heat and Control helps you bring your best products to market with efficient and reliable equipment solutions for all of your food processing needs.

Prepared foods manufacturers combine a variety of spices and seasonings and use different coating methods to create unique products and flavor profiles. Following are some common types of coating ingredients and methods of use: Pre-Dusts Pre-dusts are a blend of finely ground grain-based coatings…

There are two primary kinds of coating application systems: batter applicators and breading applicators. The desired coating characteristics, such as adhesion, thickness, consistency, texture, and appearance combined with the cooking/freezing process, will influence the application method chosen.…

The nut snack processing market uses multiple methods and recipe options to produce unique products with wide ranging flavors. To create a value-added nut snack product, snack processors employ a variety of applications, including: Oil and dry roasting Seasoning and coating Blending Oil…

What are the specific considerations for metal detection and X-ray in terms of product size? How do you design or choose a system to handle products of different product types and sizes on one line? Metal detectors and X-ray systems both utilize an “aperture” through which product must pass to be…

The Innovator is a great source for finding the latest solutions to food processing, packaging, and inspection challenges.

As a food manufacturer, you make an enormous commitment to bring a product to market, so protecting your brand in the marketplace is critical for success. The benefits are customer loyalty, improved market position, reduced liability risk, and overall positive branding of the product. However,…

The Optimal Solution Depends on the Type of Product Producing the best potato chip depends on many factors, but the fryer is usually at the top of the list. Likewise, determining the best fryer design for a potato chip processor also involves many factors. Ultimately, product quality has the…

Ishida i-Fort improves production efficiency with centralized management that collects data from all Ishida machinery and devices in your production line. This enables operators to quickly analyze the production line and to detect problems.

Reducing energy, waste, and water consumption The world's population is projected to reach 9.8 billion by 2050, so the demand for food products, already high, is expected to grow even higher. Increased population levels and consumer demand for a greater diversity of products has led to the…

Conveyors have transformed food manufacturing and have become instrumental in the design of efficient production lines. Until the 1990s, vibratory/shaker conveyors were the industry standard for potato product manufacturing. These rugged but loud conveyors had countless applications, but though…

Deliver unparalleled inspection with extremely high detection sensitivity for contaminating metals with CEIA - whether ferrous, non-ferrous, or stainless steel - for pharmaceutical products such as powders, capsules, tablets, and liquids.

A coated product’s success often depends on the quality and the consistency of its finished product. Working directly with customers to identify the correct process and equipment usually leads to success, and the ability to choose from a diverse offering of equipment increases the likelihood of…

Por 70 años, Heat and Control ha mejorado líneas de procesamiento y envasado de alimentos mediante equipos líderes del sector y experiencia única que brindan buenos resultados. Diseñamos, fabricamos y damos soporte a sistemas de procesamiento industrial, revestimiento, sazonado, transporte, pesaje…

Protecting your brand in the marketplace is one of the most important functions that a food and pharmaceutical manufacturer performs. But your investment establishing a reputation for product quality could be lost with just one safety recall. Developing and maintaining an effective, verifiable…

Weighing is an essential component in every consumer goods production line, and as a primary tool for portioning, it is imperative that its performance remains at optimal levels to ensure product quality while minimizing giveaway. Because computer combination weighing (CCW), i.e., multihead…

A modular, programmable, short-term storage solution for fresh produce capable of selective filling, auto-leveling, and variable speed discharge.

Strip fried potato products of surface-oil prior to freezing and packing. The stripped oil is recovered through a bank of cyclones and returned to the fryer oil recovery system. Solid fines are separated, and the reusable oil is transferred back into the frying system.

For 70 years, Heat and Control has been helping food, pharmaceutical, and other industries improve their products and better serve their customers. We are process and product technologists that bring science, imagination, and unmatched commitment to everything we do.

Heat and Control supports you with efficient and reliable equipment solutions for raw and fresh cut vegetables, salad, and fruit. Let us bring our world-leading knowledge, experience, and technology to your fresh produce project.

The world’s only multi-spectrum metal detector provides unique detection capability and extreme sensitivity of magnetic, non-magnetic, and even stainless steel metal contaminants and is also available in a USDA-approved design.

The highest sensitivity and accuracy of low- and high-density contaminant detection is possible thanks to a proprietary 7-step image analysis technology coupled with Ishida’s Genetic Algorithm (GA) image processing. IX-GA provides optimal sensitivity to an unrivaled range of foreign objects,…

This advanced premium weight checking series utilizes unique and proprietary digital load cell technology to deliver unbeatable accuracy and speed when inspecting the weight of packaged goods.

Gently transport product by cycling through slow-forward and fast-back horizontal motion, which neither damages product nor disturbs coatings, while providing the fastest product travel rates, maximizing product distribution efficiency.

Enhance quality control on your production line, both affordably and effectively, thanks to Ishida’s Genetic Algorithm (GA) image processing and 5-stage image analysis. This system provides reliable X-ray inspection for detecting a range of high- and low-density foreign bodies, such as stainless…

By combining a dual energy sensor with Ishida's GA technology, the IX-G2 will detect the smallest low density and thin contaminants, such as bone, shell, metal, glass, and rubber.

We offer integrated solutions from the world's leading snack packaging system manufacturer, Ishida, including multihead weighers, fillers, snack bagmakers, seal checkers, and case packers.

From unloading raw produce to frying, conveying, seasoning, packaging and inspection, we provide all the equipment and services required to make the highest quality snack foods while achieving higher capacities and lower production costs.

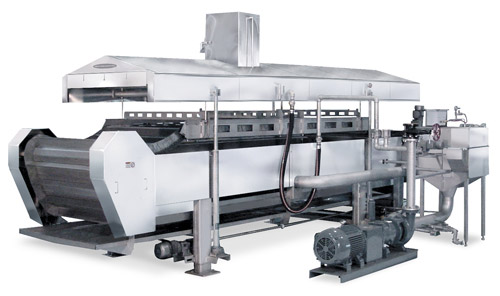

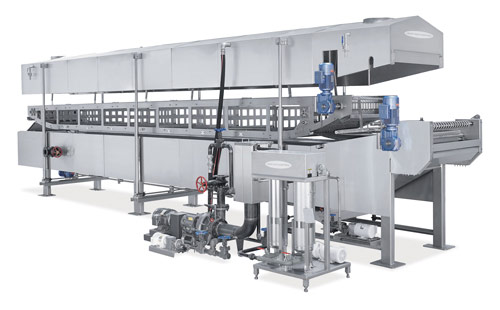

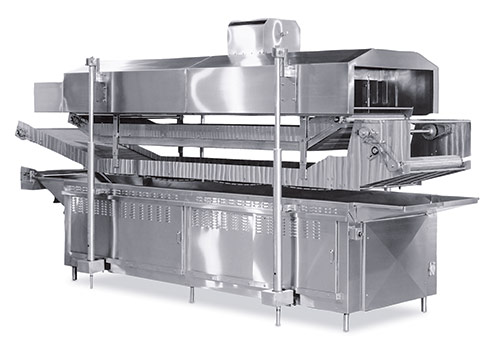

Efficient solutions for all your frying needs Mastermatic started its long legacy as one of the first manufacturers of industrial-sized continuous conveyorized frying systems. Building on this reputation with continued innovative engineering, the brand became known as the premier supplier to…

Seasoning and coating innovation meets precision application Spray Dynamics is known for being the first US-based brand devoted specifically to providing coating system solutions. Founded in 1952 by a baker in Southern California, its ever-expanding coating and seasoning systems have contributed…

STRATEGIC PARTNER World leading innovator of weighing and packaging equipment Since 1893, Ishida has innovated weighing, packaging, and quality control solutions for many industries and applications worldwide. Ishida is committed to making a producer’s ideal production line a reality. As the…

STRATEGIC PARTNER World leading innovator of industrial metal detection systems Quality control is at the core of CEIA development of the most advanced electronic and mechanical technologies for detection of contaminants accidentally present in a broad range of food and consumer products. Extreme…

STRATEGIC PARTNER Size reduction innovation Urschel equipment delivers quality-manufactured size reduction solutions for the food industry, helping food operators produce a wide array of cuts in the shortest amount of time. They continue to lead the world in size reduction technology and their…

CEIA's THS/PH21® Series and THS/PH210® Series metal detection systems offer superior sensitivity, construction quality, and reliability characteristics that make them the most suitable and effective solution to automatic elimination of metal contaminants in pharmaceutical products.

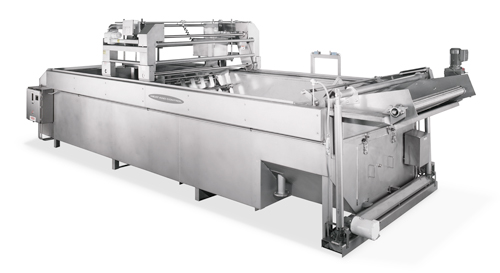

High capacity bagel boiling system that will create retarded and non-retarded bagels, and other dough products.

Improve your cannabis weighing and packaging room operations with our industry leading technologies that will help you meet demand while ensuring high quality and low giveaway.

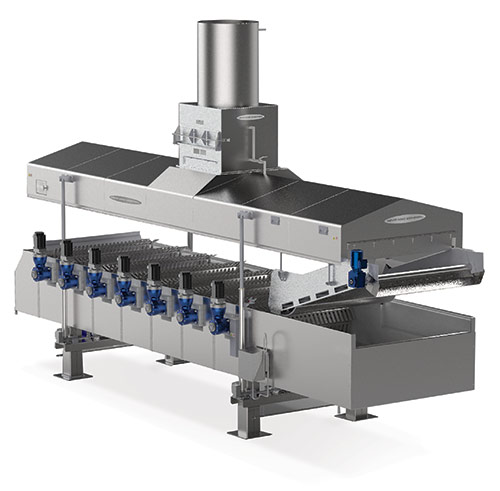

Maintain frying consistency of tortilla chips, corn chips, and tostadas with an externally-heated continuous oil circulation fryer that achieves higher capacities, lower production costs, and superior product quality.

Efficient and superior frying of a wide variety of breaded and uncoated prepared food products.

Contact Heat and Control experts located around the globe to help solve your production line challenges. Find Heat and Control locations, phone numbers, and email for questions and inquiries.

Fry-pop pellet-based snacks and extruded collets with total control to create high quality fresh product that has a long shelf life.

Contact the Heat and Control spare parts and field service teams located around the globe to help keep your line running.

Specially designed for low oil volume, precise temperature control, and clean operation, this is the ideal high-capacity roaster for uniform roasting of all varieties of nut meats.

The Spray Dynamics Two-Stage Coating System provides consistent, uniform application of liquid and dry coatings to a variety of product applications.

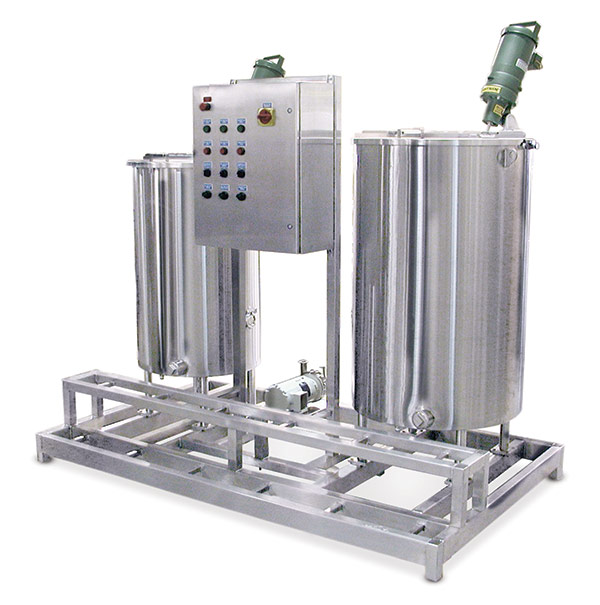

Isolating the mixing process in separate mix and use tanks improves the consistency of the blended product. The entire tank system can be heated or chilled and can be located on a skid making it self-contained and easy to handle.

Choose from multi-zone and two-stage continuous high capacity fryer systems for the most uniform french fries, formed potato products, and batter-coated fries.

Respond quickly to changing trends and get to market faster with a compact and versatile fryer that will produce many kinds of snack food products.

Form and fry consistently uniform stackable potato chips. Our proven continuous fryer and conveyor designs deliver identical single-curve chips with consistent color and long shelf life.

View our latest food processing and packaging innovations technologies to help your company achieve a new level of success.

A turnkey system that continuously processes a variety of nuts, leading nut processors count on our roasting systems for high quality products.

Accurately control temperature and conveyor speed with this direct-heated continuous fryer that can process a wide variety of prepared food products.

Accurately control temperature and conveyor speed with this direct-heated continuous fryer that can process a wide variety of snack food products.

This thermal fluid direct heated fryer cooks each piece of product at the same temperature for consistently uniform color and texture.

A compact batch fryer that will produce up to 300 lbs. (136 kg) an hour of uniform, kettle-style potato chips.

This thermal fluid heated kettle (batch) frying system will produce any style of kettle chips with high accuracy and consistency.

Our batch fryer is the ideal entry-level fryer for a new snack or prepared foods business. It's a heavy-duty fryer used for commercial batch frying and pilot production of chips, nuts, french fries, fried chicken and many other foods.

A continuous multi-zone convection system that provides optimal drying/roasting in a gentle, and sanitary manner. First-in, first-out production and even heating with a smart, step-spiral, and flighted drum design achieves uniform drying and roasting.